Innovative Insulator

Alltherm's patented Ultra-Z product was developed in the field by Alltherm Services to offer hot repairs and rebuilds to damaged linings. Specifically designed for ceramic fiber, Ultra-Z was created to withstand the heat and pressure of an operating furnace. This unique insulating material offers customers a high degree of energy cost saving while increasing the productivity of operations and equipment.

Ultra-Z is a thin coat, spray-on insulation used to seal up degraded ceramic fiber and small hard refractory cracks.Ultra-Fill is used as an insulating filler to damaged linings, while Ultra-Z operates as an insulating sealant.

The real cost benefit of our patents come from their heat saving properties. A 1/2’’ to 3/4’’ coating of Ultra-Z can lower cold face temperatures as much as 125°F. When put into figure over the life of the coating, the operating cost reduction is truly substantial.

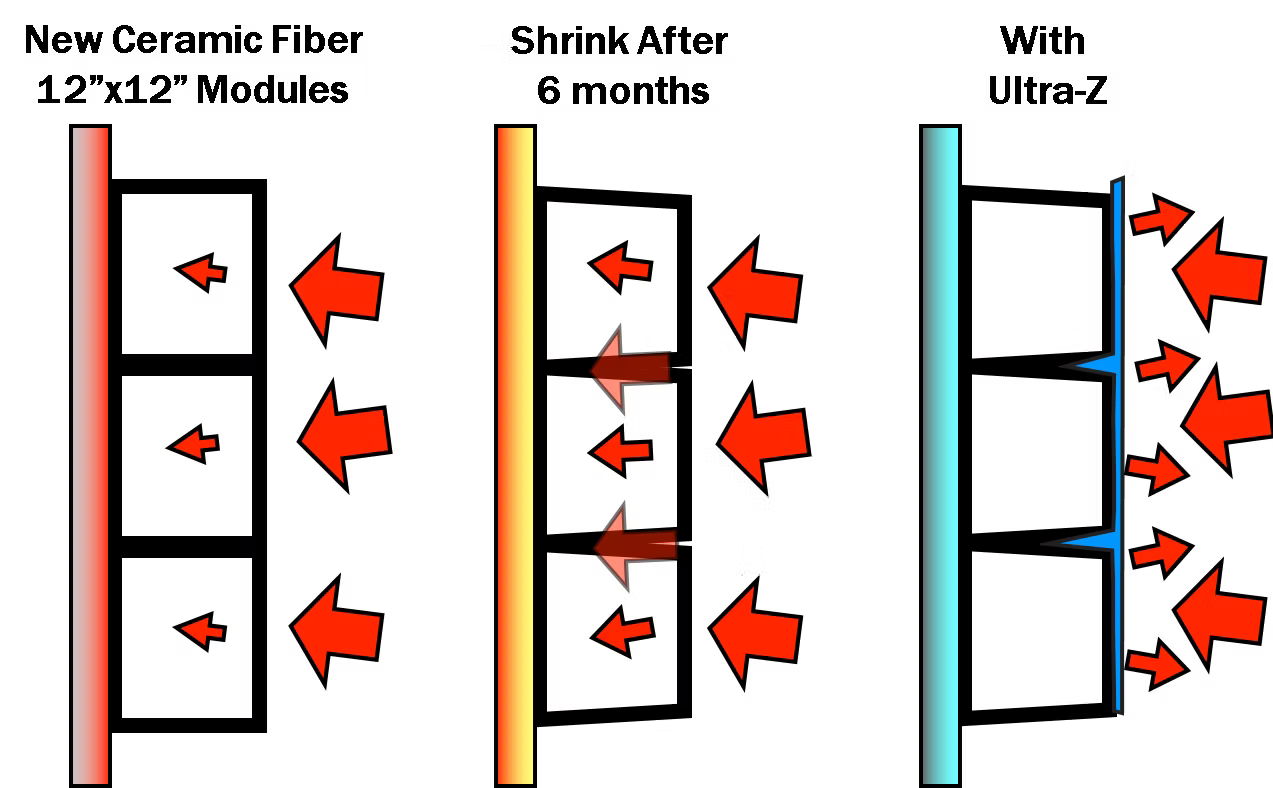

Ultra-Z products are semi-porous, high-density, spray on insulating materials. Similar to the consistency and look of wet concrete, Ultra-Z is package and shipped in five-gallon buckets. Our product is applied approximately ½”- ¾” thickness on furnace walls, roofs, and doors of hard refractory, ceramic fiber, or clean steel. We developed our spray on insulator to provide high temperature furnace operators with a quick and durable refractory repair option. Ultra-Z is excellent at filling in the cracks of hard refractory linings that are caused by the intense heat and high pressure of an operating furnace, and exceptional at filling the gaps and cracks in ceramic fiber blankets caused by shrinkage.

Insulation Value

The Ultra-Z line has a high insulation value which can lower a furnace shell temperature by as much as 125° F. Start up and reheat times are significantly reduced due to the reflective properties. The combination of these benefits results in increased furnace durability and efficiency, with customers have estimated results in fuel savings up to 10%.

One of the biggest concerns of our customers is the loss of production time. We have addressed this problem by designing Ultra-Z to be quickly and easily applied. The compounds contained in our products posses the ability to be applied to either hot or cold surfaces. In some cases, the products can still be applied while the furnace is still in operation, thus reducing downtime by as much as 30%.

Application

Ultra-Z can be applied to ladle preheater, slab and billet reheat furnaces, soaking pit covers, and aluminum melting or holding furnaces. Ultra-Z adheres to steel and stainless steel. Special applications for Ultra-Z can be discussed.

Physical Properties

- Preferred Temperature Range: 2350°F– 2750°F

- Density (After Dry-out): 36#PFc

- Estimated Coverage: 12.5 sq. ft. per pail @ 1/2’’ thick Installation Ultra-Z is pumped and air separated. For best results it is recommended that Ultra-Z be applied to 1/2’’ to 3/4’’ thick on very warm to hot surfaces.

Other Benefits

- Ultra-Z helps eliminate downtime. Repairing or rebuilding damaged linings through conventional methods can be costly with downtime and materials. But the Ultra-Z process can reduce downtime by up to 30%, as no special dry-out period is needed. A surface coated with Ultra-Z can be fully operational within hours.

- Ultra-Z Lasts Under Pressure. Unlike hard refractory linings, Ultra-Z is a semiporous, high density insulator, enabling it to withstand the immense pressure of an operating furnace. It protects the existing lining from further spalling or cracking and saves money in the long run.

- Ultra-Z Is Safer. With a low cristobalite content(.51%), it’s the smart choice for today’s steel and aluminum industries.

Silica & Cristobalite

The silica element in the ceramic fiber portion produces cristobalite when originally heated beyond 1900° F. Laboratory test have demonstrated the possibility that cristobalite is a carcinogen. As a result, we have developed an environmentally safer compound. Ultra-Z adds zirconia to the materials used in the production process. This added zirconia encapsulates the silica and does not allow it to transform into cristobalite. Other compounds have been developed that allows them to chemically set, instead of heat setting, and has eliminated product freezing limitations.

Learn More

To learn more about our ceramic fiber spray coating, check out our Ultra-Z safety data sheet.

Free Consultation

To discuss how Ultra-Z can help your facility save money, call us today at (219) 838-0227 for a free estimate.